Types of freezing of the Cold Room

The heat proof insulator, ready-made insulation panel, or Sandwich panel is the insulation panel made from using the color-coated steel having the core insulator of PS PU PUR PIR FOAM and ROCK WOOL assembled as the insulation panels to be used in making the rooms such as fire proof rooms, cold rooms, clean rooms, production line, warehouses, offices, factories, or even the houses because the insulation panels are installed easily and cheap.

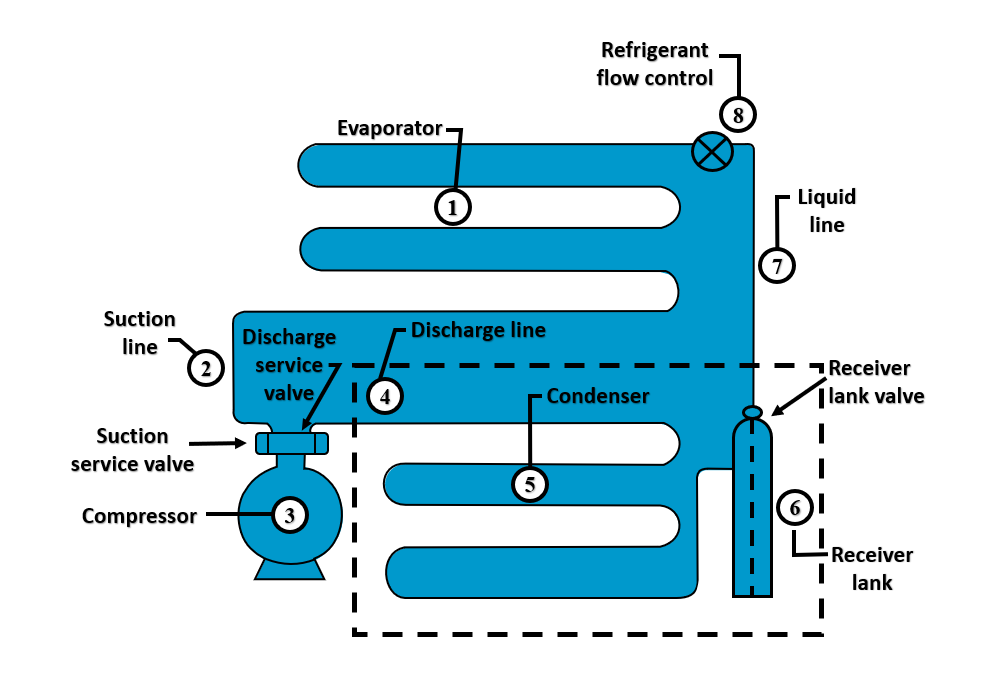

1. Direct Expansion is the system which the coolant will be delivered from the Condenser or the High Pressure Receiver through the Expansion Valve directly to the evaporator. This is popularly used with the cooling system with not much cooling size such as Individual Unit suitable to be used in the small cold room or the display windows in the department stores.

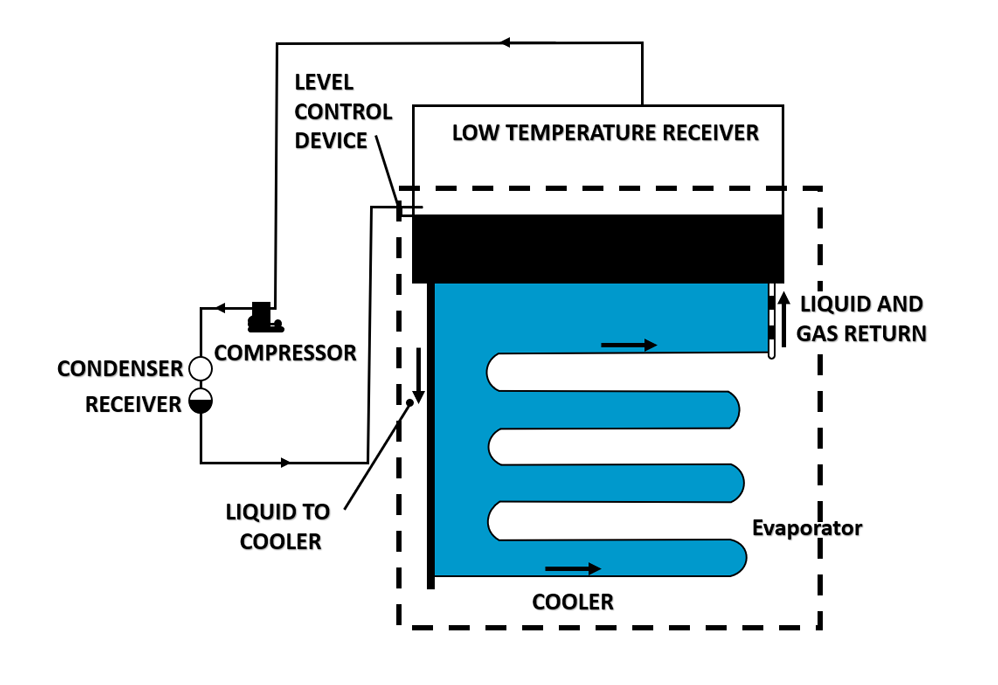

2. Flooded Coil is the system which the coolant will be delivered from the Condenser or the High Pressure Receiver through the Low Pressure Receiver. Then, the coolant will flow to the evaporator. The liquid will flow to replace gas. It is often used with the cooling system having the high cooling size. The function is centralized having the range of temperature in functioning not much. It is suitable to be used in the industry of ice cube production.

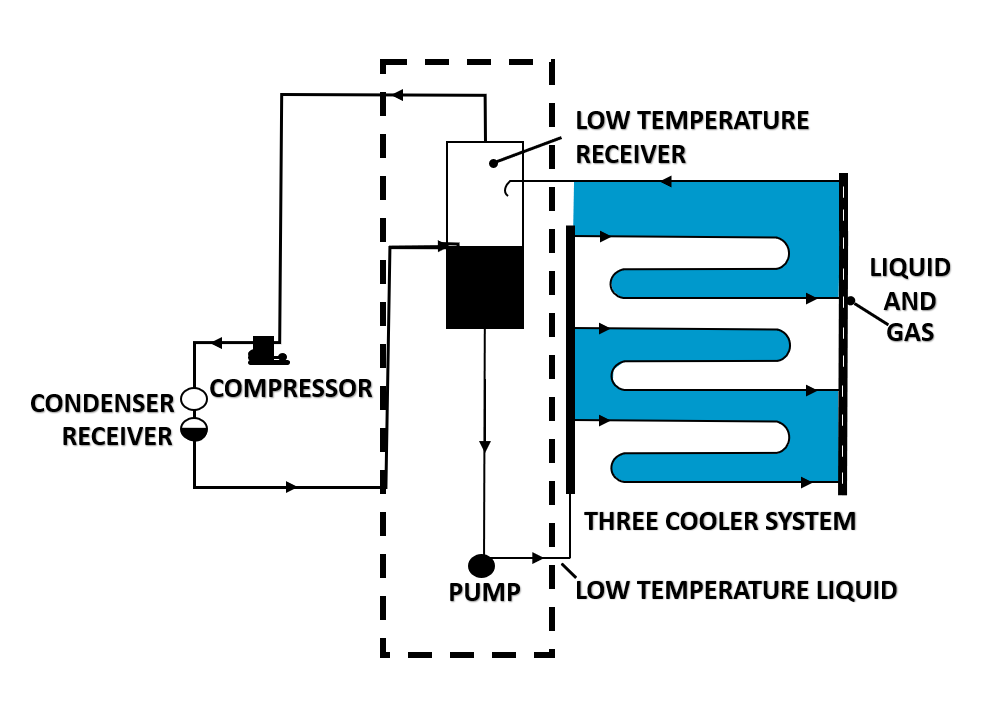

3. Pump Recirculation is the system similar to Flooded Coil except for the coolant from the Low Pressure Receiver will be pumped into the evaporator resulting in the efficiency in more cold transfer than the flooded coil. It is often used with the cooling system having the high cooling size. The function is centralized having the range of temperature in functioning very much such as being used with the cold room of -0, -18, -30, etc. It is used with the system having several sets of volatile suitable for the use in the food industry, cold room, and frozen room.