Structure Insulation Roof Panel

Insulation Roof Panel is the ready-made insulation panel or the heat proof insulation panel. This cold room’s wall has the insulation Roof with the core as PS , PU , PUR ,PIR FOAM PANEL and Rock wool PANELS, insulation roof. The Polystyrene foam and Polyurethane foam in cheap price is used. The service is provided for building COLD ROOM, CHILL ROOM, and COLD STORAGE ROOM. It is the ready-made insulation used as cold proof, fireproof, suitable for Cold room, Clean room, Chill room and Freeeze room. It is for the process room with the cheap price easily to be installed. It saves the energy. The coated ready-made insulation panel passing the rust proof process coated in 3 layers is the Panel assembled to the production with the modern sandwich panel machine with the system of U-Lock and Z-Lock.

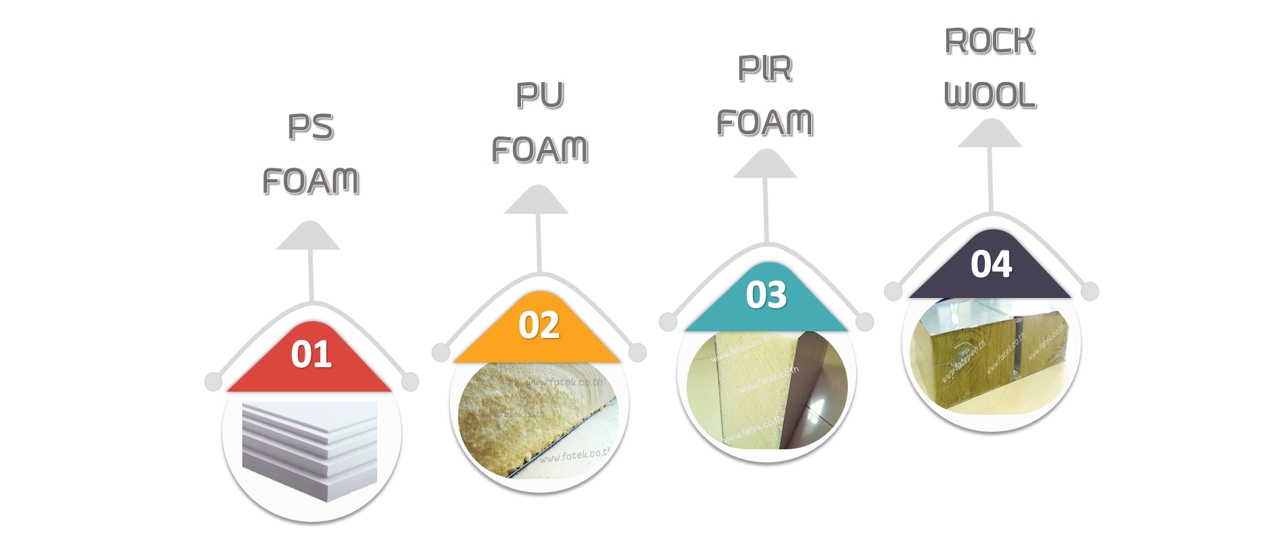

The core insulators used in producing the ready-made insulation panel or Sanwich Panel

After entering the sandwich panel machine, the sandwich panel will be gained following the sizes as desired to be used in controlling the temperature for food industry, electronic industry, and other relevant industries. The sandwich panel requires the team to install the ready-made insulation panel for working such as cold room, fruit ferment room, clean room, etc. There are various thicknesses of ready-made insulation panel from 2 inches to the thickness of 10 inches. This depends on the temperature used in controlling. The foam wall is used as the cold room insulator well.

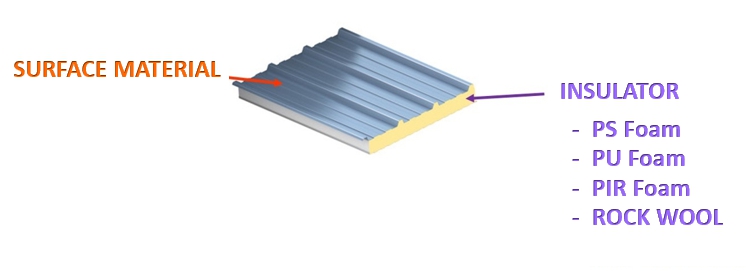

Structure of ready-made insulation panel

- Surface material: Use the color-bond material which is color-coated steel sheet ZM120 consisting of 11% of zinc – aluminum, 3% of magnesium giving the product excellent corrosion resistance. It passes the high quality coating process to pass the color coating process. The paint is not cracked with long life period and long lasting. The Food Grade complies with the laws and regulations of US Department of Agriculture (USDA).

- Insulator

- PU Foam

- EPS Foam: the Self-Extinguished insulator following the standard of fire safety

- PIR Foam which is the fire proof insulator.

- Rock wool which is the fire proof insulator.

- Adhesive glue: Use the Polyurethane glue to adhere between the steel sheet and the insulator passing the process of flattening thoroughly and continually.

- System to connect the sheet: It is used in 2 systems; U-Lock and Z-Lock systems. The obtained ready-made insulation panels are light-weighed, resist to the pressure and wind very well without being bended of the panels. Therefore, it can help preserving the temperature efficiently. It can prevent the heat to penetrate the building, prevent the coldness to get out, and prevent the humidity in the area with high humidity well